Hydraulic Top Link Assembly

Place OrderACCESORIES

TOP LINK ASSEMBLIES

-

FARMER TOP LINK ASSEMBLIES

Heavy Duty Toplinks made in 48mm tube and heavy thread size of...

-

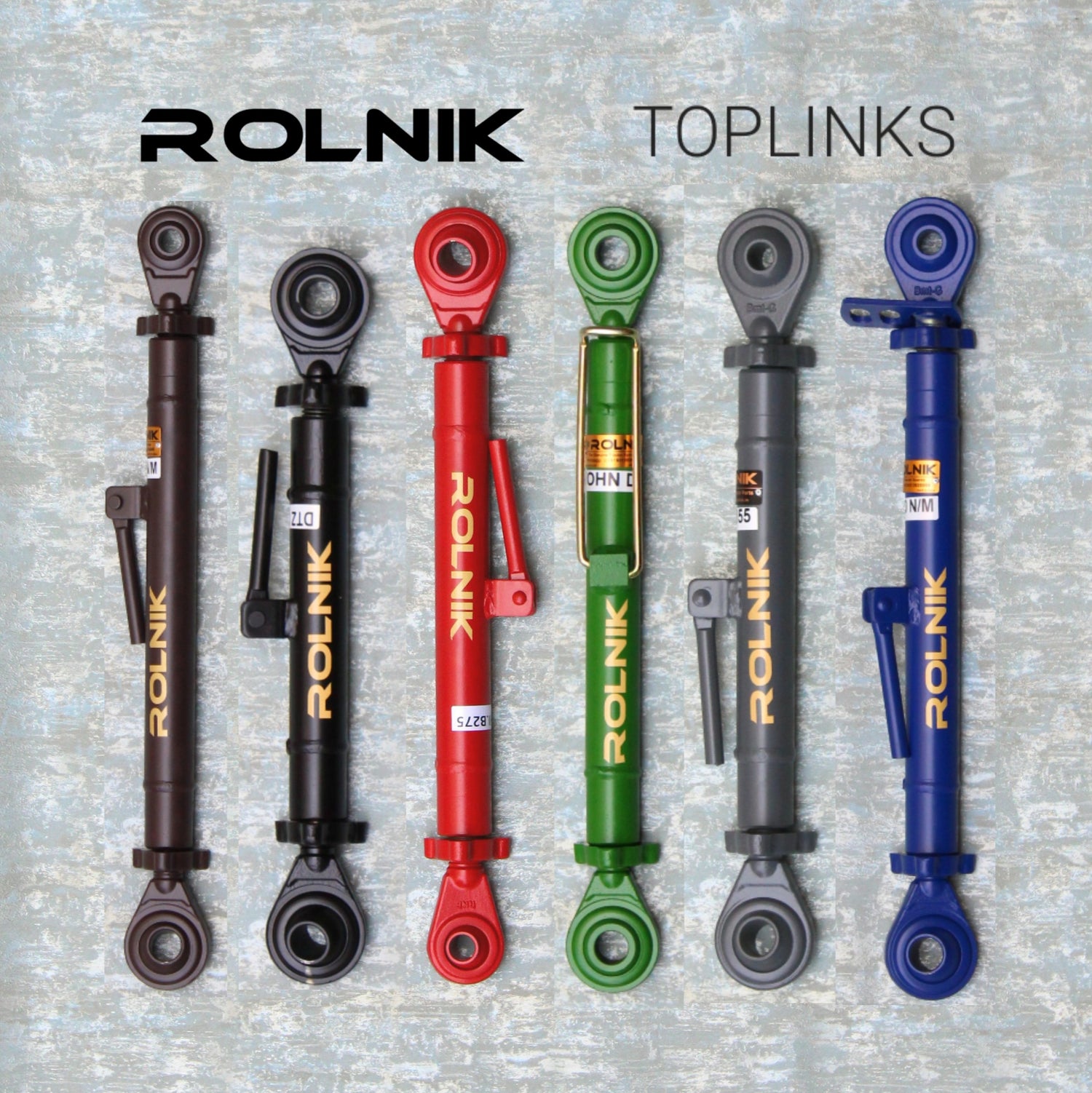

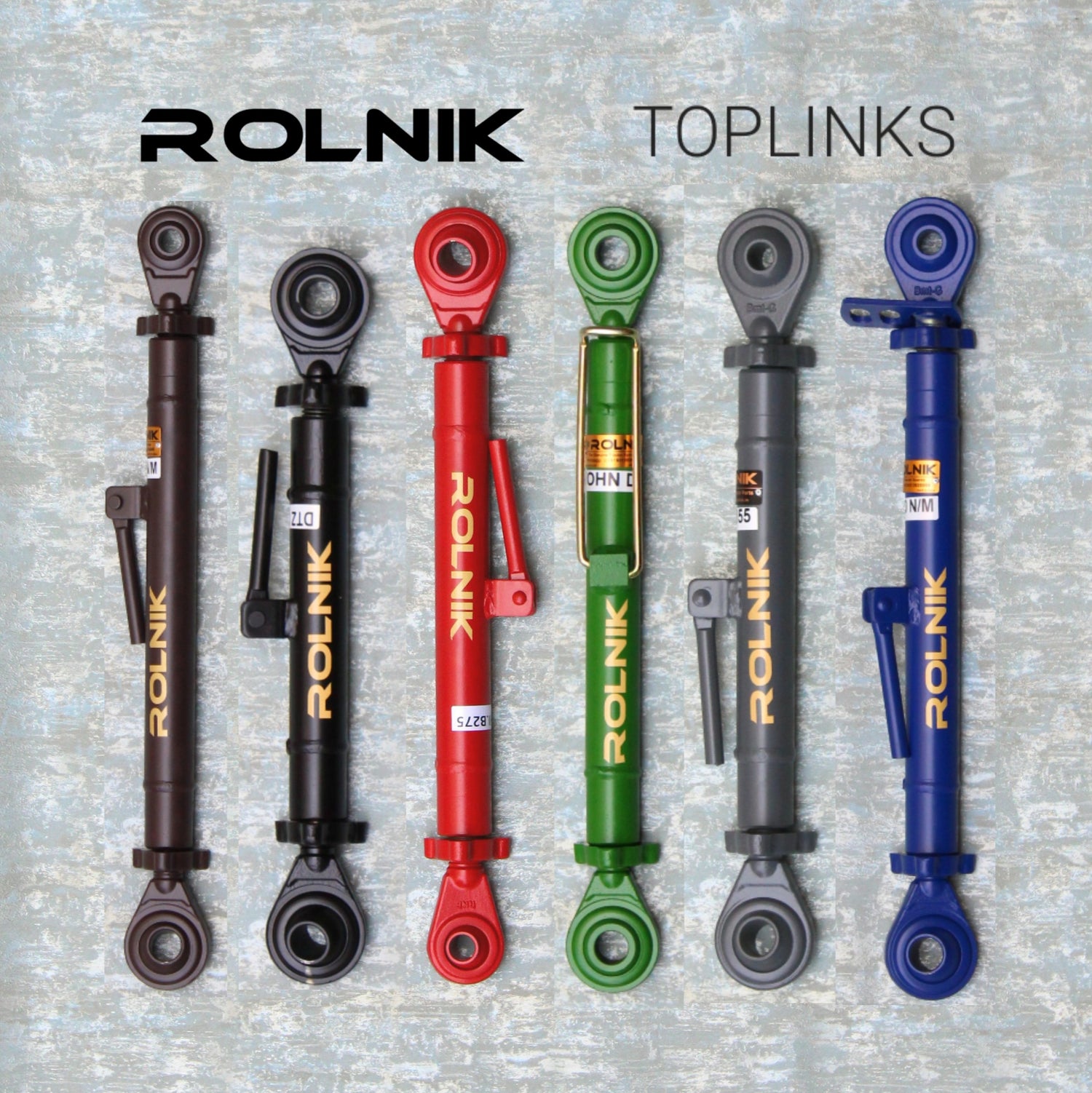

ROLNIK TOP LINK ASSEMBLIES

ROLNIK Top link Assemblies comes in 42mm Diameter heavy tube and Extra...

-

AGRICULTOR TOP LINK ASSEMBLIES

AGRICULTOR is a Registered Brand of FARMER TRACPARTS. The Agricultor products comes...

FARMER Dust Cover Toplinks (PATENT DESIGN)

LEVELLING ASSEMBLIES

-

FARMER LEVELLING ASSEMBLIES

Farmer Levelling Assemblies suitable for various tractor models are made in 48mm...

STABILIZERS & CHAINS

-

FARMER STABILIZER CHAINS

FARMER Stabilize chains comes with Tube Design which offers better protection of...

-

AGRICULTOR STABILIZER CHAINS

Heavy Duty Stabiler Chain (set of 2 pcs)

Y-ROD ASSEMBLIES

-

FARMER Y-ROD ASSEMBLIES

FARMER Y-ROD assemblies or Left Hand Levelling Assemblies are made in 48mm...

Tractor 3 Point Linkage Systems

ONLINE STORE

FARMER | AGRICULTOR | ROLNIK

FARMER TRACPARTS in Auto Expo (Delhi)